Battery dryrooms play a vital role in the battery industry, ensuring optimal performance by maintaining low humidity levels, preventing moisture-related issues, and promoting consistent manufacturing processes. Maintaining a constant and ultradry humidity level requires a lot of energy, dryrooms represent 43% of the total energy used in the battery production process. A specially dimensioned Heating, Ventilation and Air Conditioning (HVAC) system is required to operate a dryroom and so accounts for a substantial part of the total energy demand in battery cell production.

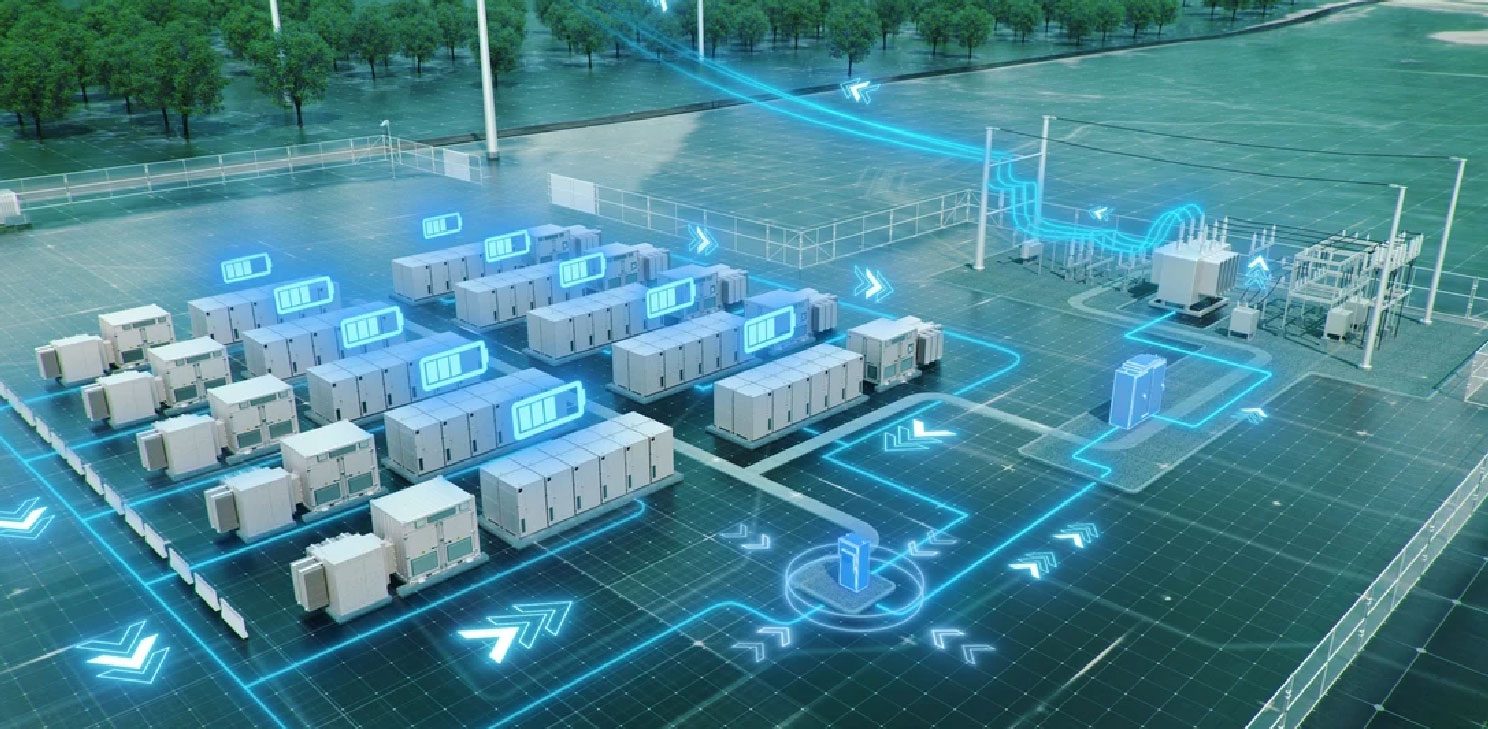

HVAC systems in these environments are essential for regulating temperature, humidity, and air quality, which directly affect the performance and lifespan of batteries. HVAC systems account for a significant portion of energy consumption, making their efficiency a priority for facility management. One of the best ways to increase efficiency is implementing advanced control strategies. By utilizing smart technologies and IoT (Internet of Things) solutions, gigafactories can monitor and adjust HVAC settings in real-time. This allows for dynamic responses to changes in production activities and external weather conditions, significantly reducing energy waste.

Another way to increase efficiency is the integration of energy recovery systems. These systems capture and reuse waste heat generated from industrial processes, contributing to a more sustainable energy model. By recovering this energy, gigafactories can lower their dependence on external energy sources, further enhancing HVAC efficiency. The design of HVAC systems also plays a critical role in their efficiency. The study suggests that adopting modular designs can improve performance by allowing for scalability and adaptability as production needs change. Modular systems can be tailored to specific areas within a gigafactory, ensuring that energy is used where it is most needed.

By powering HVAC and gigafactories as a whole with renewable energy sources, such as solar panels, gigafactories can significantly reduce their carbon footprint while maintaining energy efficiency. This not only aligns with global sustainability goals but also offers long-term financial savings.

SEMCO | FläktGroup, Gold Sponsor of our upcoming event the 2nd Battery Gigafactory Summit USA, is a global leader in air management specializing in the design and manufacture of a wide range of air treatment and air movement solutions. FläktGroup has a full range of ventilation and air treatment solutions for battery production, to be used for the process with NMP, N-Methyl-2-Pyrrolidon, recovery solutions, fresh air production equipment or dry room design and construction.

By leveraging advanced control strategies, energy recovery systems, modular designs, and renewable energy, these facilities can improve their operational efficiency and sustainability. As the industry continues to evolve, prioritizing HVAC efficiency will be key to fostering a more sustainable future for battery production. To meet with FlaktGroup Semco and their representatives, network with peers and solution providers and attend talks from industry leaders, book your place to attend the 2nd Battery Gigafactory Summit USA: Advances in Planning, Engineering and Operations taking place in Nashville, Tennessee, on November 13–14, 2024.

For more information, visit our website or email us at info