The 4th Autonomous Off-Highway Machinery Technology Summit took place from May 21st to 22nd, with attendees from all over the autonomous off-highway machinery industry coming together at the Holiday Inn Berlin Airport Conference Centre. The two day conference had a wide and comprehensive agenda that involved dozens of presentations from expert speakers, panel discussions, and networking breaks.

Our attendees learned and exchanged knowledge on cutting-edge developments, autonomous machines, AI and deep learning, and advanced sensor technologies, software, and data management, alongside the regulatory and ethical considerations that accompany these innovations

This article will provide a session recap for those who didn’t get the chance to attend and serve as a reminder for those who attended.

Artificial Intelligence Act and correlated legislations. Is compliance by design feasible?

Francesca Hennig-Possenti, AI Senior Legal Counsel at John Deere

Francesca spoke about the AI act and correlated legislation that serve as the EU’s Digital Strategy when it comes to regulating artificial intelligence. Annex III of the AI Act outlines that an AI system is classfied as high risk if it is a product covered by legislation in Annnex I, it is intended to be used as a safety component for products listed in Annex II, is included in Annex III and is required by legislation in Annex I (e.g. Machine Regulation) to undergo a third-party assessment. AI that is classified as high risk has different requirements to follow, such as needing a risk management system (Art. 9.1-4), data and data governance requirements (Art. 10) and robustness and cybersecurity measures (Art. 15). Machinery regulation might be required to undergo a third-party certification if the machine entails safety components with fully or partially self-evolving behaviour using machine learning approaches ensuring safety functions.

Connecting Early-Stage Physical Design, Autonomy and Functional Safety in Off-Highway Machinery

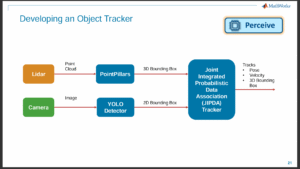

Christoph Kammer, Application Engineer, Steve Miller, Product Manager and Remo Pillat, Autonomous Systems Development Manager, at MathWorks

The trio from Mathworks began their presentation with a case study that showed that simulation and virtual testing are key technologies to reduce cost and mitigate risk. They described using models with essential physics and accurate sensor positions with a vehicle suspension model. The model can be tailored to match the requirements of the virtual test and explore other aspects of performance, including component choice, efficiency, and electrical technology. Perception for autonomy and safety can be tested with closed-loop, deterministic simulations with Unreal Engine that has collision detection and physics of non-Simulink actors which provides information that can be used in MATLAB and Simulink. They concluded that capturing physical behaviour at the right level of detail enables effective virtual testing, connecting with a game engine enables sensor data collection and world interactions, and system-level integration enables testing and validation of autonomous systems.

From Machines to Robots: Why Construction Needs a Seat at the Table

Estefania Betancourt, Team Lead Construction Automation and Robotics at PORR AG

Estefania outlined key definitions of innovation, construction machines, and robots to clarify the spectrum from machinery to robotics and its implications for the construction sector. She highlighted the need to bridge the gap between OEMs and end-users, as R&D cycles often move faster than the realities of construction sites. Lab conditions do not reflect unpredictable site environments, and OEMs frequently design for ideal rather than real-world scenarios. She advocated for an innovative ecosystem where manufacturers and construction firms form partnerships beyond traditional sales relationships, collaborating to co-develop autonomous solutions that enhance efficiency on-site.

Robotics Technologies for the Construction and Agriculture Sectors

Marta Niccolini, Robotics Group Leader at Yanmar R&D Europe

Marta opened her keynote with an introduction to Yanmar and its business areas. She presented the current state of robotics in construction and agriculture, driven by labour shortages, productivity demands, and safety needs. However, adoption is limited by complex, unstructured environments, lack of regulations, safety concerns, high costs, limited performance and flexibility, user difficulty, and untrained operators. Yanmar is actively contributing to the agricultural robotics revolution through the smartification of conventional machines and the development of new field-ready robots. Key technologies include autonomous guidance, attachment control, environment recognition, people and obstacle safety systems, and sensing and data management.

Controlling robots from orbit: how teleoperation can pave the way for autonomous systems

Thomas Krueger, Team Lead Human-Robot Interaction Lab at the European Space Agency (ESA)

Thomas introduced experiments on the Space Station involving teleoperation, particularly the remote control of robotic arms. He discussed teleoperation’s key role in the development of autonomous systems as a foundation, fallback, and enabler. Advances in global communication, including city-wide 5G and low Earth orbit constellations like Starlink, are renewing interest in teleoperation. Despite promises of robotic autonomy since 2011, teleoperation remains vital. It requires communication with moving vehicles, adaptability to changing networks, sophisticated software for dataflow management, smooth transitions between autonomous and manual control, and strong safety and scalability measures.

Artificial Intelligence systems for automation and autonomy in off-road applications

Luca Ferrari, Global Manager of Robotics and Breakthrough Technology at CNH Industrial

Luca addressed the technical challenges of off-road environments, particularly Visual Degraded Environments (VDE) caused by dust, fog, rain, vibrations, and varying lighting conditions, requiring systems to operate effectively both day and night. CNH’s current AI systems, such as the Intellisense on the Combine Harvester, help automate and optimise machine settings to reduce grain loss, improve quality, and save fuel. He introduced the XMANAI EU project, focusing on the role of Explainable AI in manufacturing. A key trend is the shift from mechanics supported by electronics and software to electronics, software, and data supported by mechanics. The future of farming is a balance of human expertise and machine intelligence for sustainable productivity.

Automated Agricultural Machinery and Robots

Julius Schoening, Professor at Osnabrück University of Applied Sciences

Operational Design Domains (ODDs) and Dynamic Driving Tasks (DDTs) are necessary for safe and functional autonomy. Data from specific ODDs must include rare events and geographical nuances. Legal compliance for AI is increasingly important, with changing requirements from controlled tests to widespread market use. A proposed XAI platform aims to support developers legally throughout the lifecycle by enabling legal assessment, guiding dataset use, and ensuring explainability.. Future work will focus on model-agnostic methods and comparing AI and human decisions.

Reliable Real-Time Localization for GNSS-Challenged and All-Weather Mobile Work Machines

Jose Peralta, CTO at GIM Robotics

Jose discussed how GIM Robotics accelerates autonomous development with modular solutions to reduce time-to-market. Their PAIKKA software delivers 3D positioning in GNSS-limited and harsh environments using natural feature localisation, motion estimation, and 3D map matching. Tested in forests, construction sites, underground mines, and ports, PAIKKA enhances mobile machinery’s safety, precision, and efficiency across diverse applications. Key takeaways include overcoming localisation challenges through sensor fusion and resilient mapping, even under obtrusive weather and blocked GNSS signals. Integration is simplified, enabling consistent deployment across platforms. Looking ahead, GIM aims to shape the next wave of autonomy by supporting scalable, explainable, and regulation-compliant systems that improve operational value, safety, and usability.

From Theory to Reality: Lessons from Deploying AI in Autonomous Machinery

Bilaal Khan-Cheema, Lead Automation Field Engineer (EMEA) at (Ex-) Hyster-Yale Group

Bilaal spoke about how AI in industrial autonomy is seen as plug-and-play, but real-life deployment introduces unpredictable failures. Assumptions made in lab conditions may not hold in the field due to physical, human, and environmental variations. Sensor drift, poor connectivity, terrain changes, and hardware mismatches can affect performance. Site variations, safety concerns, and operator workarounds can disrupt AI models, real-world operators often bypass systems for efficiency, and unpredictable site layouts or weather conditions can change consistency. The best AI should not just be about the best model, but should account for real-world unpredictability. This means building adaptive systems that respond to live telemetry, incorporating human override feedback into learning loops, and ensuring integration with actual user behaviour. Human-machine symbiosis is essential, co-pilot models that support operators outperform fully autonomous systems in many industrial contexts. To succeed, developers must focus on integration, diagnostics, and operator trust from the start.

Automation technology to enhance safety, efficiency and productivity in mining

Sickandar Shaffic Ahmed, IT Business Partner and CIO – Load & Haul at Sandvik Mining and Constructions Oy

Sickander shared his insights on how automation technology is key to improving safety, efficiency, and productivity in mining. Autonomous and remotely operated mobile equipment play a vital role in reducing risk and enhancing output. Proximity Detection and Collision Avoidance Solutions (CAS) prevent accidents by identifying personnel and machinery in close range. Health and safety monitoring systems ensure compliance with safety protocols and provide real-time alerts during emergencies, helping to protect workers on site.

EIC deep tech funding in electrification and autonomous machines

Franc Mouwen, Program Manager at EIC

Franc shared how construction is facing a perfect storm: rising demand for buildings, infrastructure, and renovations; the push for carbon neutrality and circular practices; low productivity; labour shortages; and rising costs. We must focus on transitioning to zero-emission job sites. Decarbonisation strategies include changing how we design, fabricate, and use materials, alongside choosing new, sustainable materials. The Pathfinder Challenge 2025 aims to develop autonomous robot collectives capable of collaborative tasks in dynamic, unstructured construction environments. It targets a future digital production and assembly chain through a simplified structural material-robot system and an autonomous multi-robot platform, demonstrated via robotic building assembly sequences.

Challenges in Legislation, Guidelines, and Standards

Nihada Poricanin, Manager Compliance and Support Residential Robotics, R&D Robotics at Husqvarna Group

The updated EU Machinery Regulation (2023/1230) replaces the previous Machinery Directive, introducing requirements for AI, cyber safety, and autonomous or remote-controlled machinery. It requires notified body assessments for certain products and allows digital Declarations of Conformity and Operator Manuals. All Husqvarna machinery, including electric and battery-powered, is in scope across CE-marking markets. Key challenges include evolving legislation, outdated industry standards, and fragmented IoT regulations. Without global certification, businesses face inconsistency, increased costs, security risks, and barriers to trade. This lack of interoperability can also negatively affect innovation and slow down technological progress.

Unleashing the Power of AI at KION

Mohamed Bakr, Technical Director AI at KION Group

Mohamed spoke about how AI for robotics combines computer vision and machine learning to enable machines to interpret and analyse visual data. Key functions include object detection and recognition, visual inspection, defect detection, and scene understanding for navigation. Generative AI is also being explored for robotics and internal company processes. Benefits include keeping data secure within the company, platform-wide Single Sign-On authentication, and the application of corporate-specific guidelines. Users can choose between different LLMs, with features such as individual chat artefact storage. Future functionalities may include LLM selection, chat export, web search, agents, and analytics.

Sponsors

The 4th Autonomous Off-Highway Machinery Technology Summit was supported by a wide range of sponsors who brought their teams to our exhibition hall, and Innovatrix would like to thank them again for their support.

If you want to attend our next autonomous off-highway summit and have the opportunity to hear presentations like these and many more, join us for our American edition this December. To discover the latest innovations and trends in robotics and autonomous off-highway machines, meet with solution providers and hear talks from industry leaders, attend AOMTUSA – the 5th Autonomous Off-Highway Machinery Technology Summit taking place in Louisville, Kentucky, USA on December 10-11, 2025.

For more information, visit our website or email us at info@innovatrix.eu for the event agenda. Visit our LinkedIn to stay up to date on our latest speaker announcements and event news.